Learn about air brakes for combination vehicles in the state of New York.

CDL Air Brakes S.6.2—Combination Vehicles | New York State

Closed Caption

Introduction

Hi there smart drivers, Rick with Smart Drive Test talking to you today about chapter 6 section 2 of the New York CDL manual.

This is for students working towards their CDL license, and requiring air brakes as part of that CDL license.

This is the part of air brakes that applies to trailers.

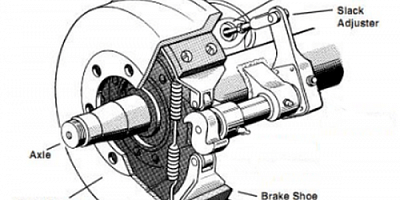

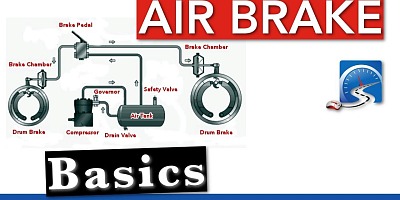

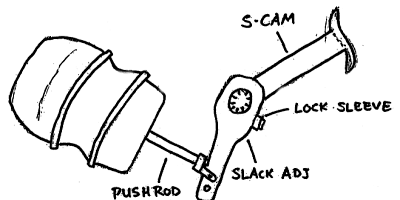

One of the things that you need to know about trailers and trailers that are equipped with air brakes is that it has all the same parts as what is on the truck: air lines, brake chambers, push rods, slack adjusters, "S" cams drums and linings.

Don't Work the Day for Free:: DOT Weigh Scale Checklist |

||

• DID YOU KNOW? :: Bus & truck drivers are the only drivers that have their own police force (DOT, CVSE, MTO, etc.);• SMART :: There's a lot of paperwork you must produce for authorities at the weigh scale;• SELF-CONFIDENCE :: Bring all paperwork in one hit & impress the diesel bears! |

||

Because in most cases, it's you that gets the fine...NOT the company! |

All of those components are the same.

As well, it has service brakes, it has parking brakes, and the trailers have emergency brakes, which are powered by air pressure, which are the service brakes obviously.

And the spring brakes apply the parking brakes and the emergency brakes.

So, all of the components are the same.

Trucks that pull semi-trailers equipped with air brakes have a tractor protection system.

and we'll talk about that in more detail.

The tractor protection system on an air brake equipped vehicle protects the tractor's air supply in the event of a catastrophic air loss in the trailer.

So today we're going to talk about the New York CDL manual - chapter 6 section 2, which is trailers equipped with air brakes.

And we'll be right back with that information.

[OPENING CREDITS & MUSIC]

6.2 – Combination Vehicle Air Brakes

Hi there smart drivers, welcome back.

Rick with Smart Drive Test talking to you today about the New York CDL manual chapter 6, section 2, which deals with trailers and air brakes on semi-trailers, or trucks that are equipped to pull trailers that have air brakes.

All of the trucks that are equipped to pull trailers that have air brakes are equipped with tractor protection systems.

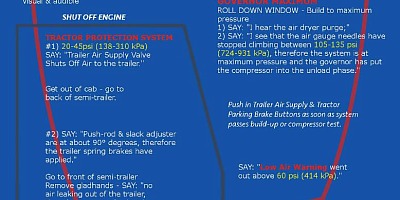

Tractor Protection System

The tractor protection system consists of the tractor protection valve--just to confuse you--and the trailer air supply valve on the dash.

The tractor protection system consists of the tractor protection valve--just to confuse you--and the trailer air supply valve on the dash.

And we're going to talk more about that.

The truck that is designed to pull a trailer with air brakes will have a tractor protection valve & a tractor protection system.

Engineers called those two things the same thing just to confuse you.

The tractor protection system and the tractor protection valve.

And just to confuse you even farther, the tractor protection valve is part of the tractor protection system, which consists of the tractor protection valve and the trailer supply valve.

Those two valves make up the tractor protection system.

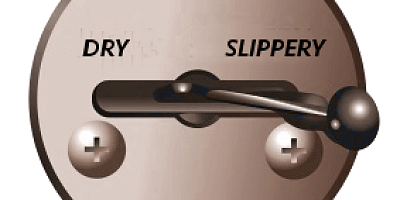

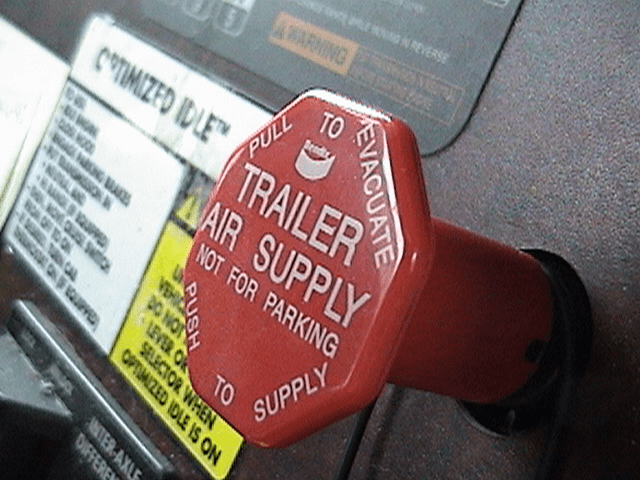

The trailer air supply valve is the eight-sided red button on the dash in the truck.

And you see the image here of the trailer air supply valve.

The reason the engineers called it the trailer air supply valve--oddly enough--it supplies air to the trailer, thus they called it the trailer air supply valve.

The trailer air supply valve-- to try and make it simple--is nothing more than a switch - on/off.

It turns air on and off to the trailer.

And I'll give you some more explanation about the trailer air supply valve later on in the video.

So all trucks designed to pull trailers with air brakes have a tractor protection system.

And the tractor protection system is to protect the tractor's air supply in the event that there's a catastrophic air loss in the trailer, thus the tractor protection system.

It protects the tractor's air supply.

6.2.1 – Trailer Hand Valve

The trailer hand valve, located up underneath the steering wheel, maybe on the dash, depending on which truck you're driving.

Question on the test - get this right out of the way: not to be used for parking!

Question on the test - get this right out of the way: not to be used for parking!

That is the question on the CDL license test - not to be used for parking - do not use it for parking.

The trailer hand valve applies the trailer service brakes independently of the truck.

So if you're going down the road, you can pull the hand valve down and apply the trailer brakes independently of the truck.

Now in the old days they were called "broker brakes".

In the manual they call them a the "Johnson bar" or "trolley brake." They're called all kinds of things, but in this day and age, they're becoming redundant and there's actually some tractors that are now not having a trailer hand valve on them.

The only thing that we really use hand valves for was hooking up to trailers that didn't have spring brakes pre-1975.

Essentially we don't use them anymore - you just put your foot on the brake pedal and it applies all the brakes on the unit evenly.

So the question on the test: not to be used for parking and certainly don't use it going up and down the road because it's not like a conventional brake.

Its kind of...you can't really tell how much you're putting it on.

So unfortunately, if you're going down the road and you start using the trailer brake, you're most likely going to lock up the trailer brakes and that trailer's going to start coming around and you could risk a jackknife.

So don't use it.

Question on the test - not to be used for parking.

6.2.2 – Tractor Protection Valve

The tractor protection valve and the trailer air supply valve are the two valves that make up the tractor protection system.

The tractor protection system protects the tractor's air supply in the event of a catastrophic air loss in the trailer.

So for example, the trailer drops off the back of the truck and rips the airlines off, the tractor protection valve is the guard - it detects the air loss in the trailer and tells the trailer air supply to shut off air to the trailer.

Thus it's called the trailer air supply.

Some of the valves in the system the engineers actually got right--trailer air supply-- it's essentially a switch - on and off.

6.2.3 – Trailer Air Supply Control

It supplies air to the trailer or it turns the air off to the trailer.

Think of the trailer air supply a little bit like an electric light switch.

The electric lights which doesn't turn the light off and on.

It actually controls electricity and subsequently the light goes off and on.

The same thing with the trailer air supply: it controls air to the trailer and turns air off and on, and subsequently the parking brakes go on and off on the trailer.

So the trailer air supply and the tractor protection valve are the two valves that make up the tractor protection system.

The system protects the tractor's air supply in the event of the trailer losing air.

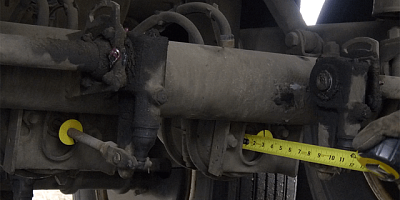

So the tractor protection valve is the valve that the two lines--the glad hand lines--are plumbed into on the back of the truck, and you can often see the lines plumbed right into that valve.

The trailer air supply valve is an eight-sided octagon valve-- octagon-shaped valve--it's red and has trailer air supply written on it if the truck isn't too old and it isn't worn off.

And you push it in to supply air to the trailer and pull it out to evacuate air from the spring brake chambers in the trailer and put the parking brakes on in the trailer.

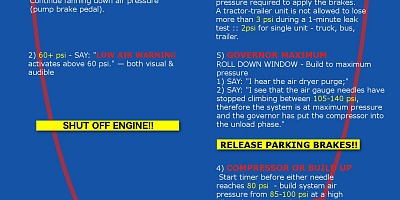

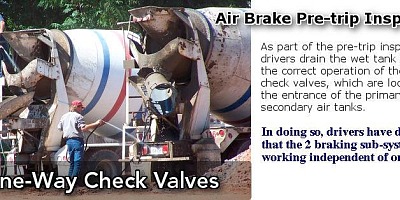

The tractor protection system is part of your pre-trip inspection - when you fan down in the cab to between 20 and 45psi to test the spring brakes apply automatically on the truck, the spring brakes on the trailer will also automatically apply.

So the four-sided yellow button--the parking brake valve will pop out and the trailer air supply button will also pop out and the spring brakes will apply on the trailer.

Spring Brakes

Most trailers in this day and age will all have spring brakes.

If you're all specialty equipment on lowboys and those types of things, maybe they won't have spring brakes or something pre-1975.

But I've been around the industry since the early-1990s--more than 20 years now--I've never encountered a trailer that doesn't have spring brakes on it.

So it's very unlikely, in this day and age, that you're going to encounter a trailer that doesn't have spring brakes on it.

But in the event that you do, you can hook the lines up before you back under it.

Push in the trailer supply, pull down and hand valve and then back under the trailer so it doesn't run away on you.

As well, when you park them and unhook, you gotta block the wheels.

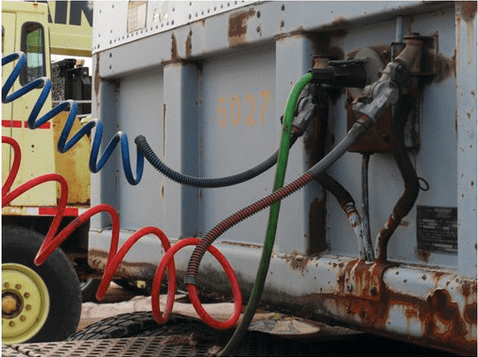

When you hook up to the trailer, there is commonly called the lines which, which are the two airlines and the electrical line.

We're not going to talk about the electrical connection.

6.2.4 – Trailer Air Lines

But we'll just talk about the airlines.

The airlines are the only airlines on the airbrake system that are color-coded.

There's a blue line and a red line.

The blue line is called the control line or the service line, and the way that I remember it is that "the blue line controls the service brakes." So it can be called either the control line or the service breaks.

The red line is the emergency or supply line and the reason it's called the supply line is because it fills the air tank in the trailer and fills the air brake chambers releasing the spring brakes, and thus the parking brakes keeping them off when you're going up and down the road.

In the event of an emergency that the emergency line becomes detached or one of the lines rips, or ruptures in the trailer, it is also the emergency line because the tractor protection valve will detect catastrophic air loss in the trailer and tell the trailer air supply to shut off air to the trailer.

Therefore it's called the emergency line because the emergency brakes on the trailer will apply.

Therefore it's called the emergency line because the emergency brakes on the trailer will apply.

When you hook the lines up, the red line--the emergency supply line--always goes on the driver side.

If you hook them up backwards, the spring brakes won't release.

So if you get in the truck and try to pull away and the trailer brakes won't release, get out and make sure that you've got the glad hand hooked up correctly.

The red line goes on the driver's side - it is always on the outside.

As well, in this day and age, because you know we're not always awake and sometimes we're tired, the glad hands are now polarized so you can't actually hook them up backwards.

You can only hook them up one way.

Airlines: red and blue -blue goes in the inside the red goes on the driver's side.

The blue line is called either the control line or the service line and controls the service brakes going up and down the road.

When you push down on the brake pedal or pull down on the hand valve.

The red line is the supply line which supplies air to the air tank and put air into the spring brake chambers keeping the parking brakes/emergency brakes off while we're going up and down the road.

In the event that there's a catastrophic air loss in the trailer, the tractor protection valve will detect air loss and tell the trailer air supply valve to shut off air to the trailer.

And in that event, the emergency brakes on the trailer will apply.

6.2.5 – Hose Couplers (Glad Hands)

The hose coupler on the end of the airlines are called the glad hands and as I said previously, the reason they're called glad hands is because they're happy to be hooked up.

Now to hook them up, you simply meet the two rubber seals together like this at a 90° degree angle and push it down and the two will lock into place.

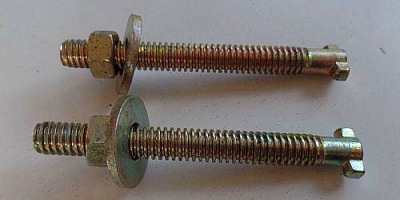

One of the questions on the license test is: what is the most common cause of air loss in trailers?

And the answer is: defective glad hand seals.

There are little rubber seals in there and if you can wield a flat ended screwdriver, or a butter knife, you can pry that seal out of there and replace it.

You can pick them up at a truck stops for a couple of bucks.

I'll tell you the other thing about driving truck, I've been around trucks and buses for more or less 20 years - I've never replaced the glad hand seal - they're robust.

We gotta love technology and materials and those types of things.

They're just a lot more durable and it's not likely you're going to have to replace the glad hand seal, but for the purpose of the license test that's the answer to the test: glad hand seals become defective and have to be replaced.

One of the warnings they have here in the manual is that if you cross the lines on an older trailers that don't have spring brakes on it - you can potentially drive away, but you're not going to have any brakes on the trailer.

Now let me tell you from a bit of experience, you don't need to have very much experience—a couple of months in the seat—and you're going to know that there aren't any trailer brakes back there in that trailer.

Because trailers.

if they're loaded can weigh anywhere from five to eight times what the tractor weighs.

And if they're loaded and you don't have any trailer brakes back there, you know that that trailers pushing.

If so, get out and put the lines back on correctly.

| The red goes on the driver's side and the blue lines always goes on the inside. |

That's the way you hook up the lines correctly.

As well, when you unhook the trailer you need to stow the lines.

Most trucks that are capable of pulling trailers equipped with air brakes will have dummy couplers.

They're couplers that you just put them in and these keep dirt and water and other contaminants out of the airline.

So use the dummy couplers.

A lot of guys will just use a bungee strap on the deck on the back of the truck.

Ahh...

if you have dummy couplers, put them in the dummy couplers - it just keeps the air brake system clean.

All trailers and dolly converters will have air tanks to store air for the application of the service brakes and to keep the spring brakes off at the trailer axles.

6.2.6 – Trailer Air Tanks

And one of the ways that we do this is that in the back of the trailer--without trying to get too technical--there's a relay valve and the reason we call the blue line the control line is because it sends a signal to the relay valve and tells it to make a brake application of whatever pressure you made on the foot pedal or the hand valve.

So say for example you made a 10-pound brake application, the blue line sends a signal of 10 pounds back to the relay valve the relay valve pulls 10 pounds of pressure directly from the air tanks and sends it out to the service brake chambers, thus reducing brake lag in the system.

Relay Valve

Another way you can think of the relay valves and the system is kinda like if I want to send flowers to my Mom in Ontario 2,000 miles away.

Well I wouldn't drive there and go buy flowers at the local flower shop and take them to my Mom because that's really slow.

Because it takes three days to drive to Ontario and then three days to come back.

Rather what I would do is I would pick up the phone, call the local flower shop and tell them to send flowers out to my Mom.

That way I could do it in a matter of a couple of minutes.

It's the same thing as the relay valve on a trailer ,60 feet away from the driver.

It sends a signal back to the relay valve, the relay valve says ok, you want 10 pounds of pressure to the service brake chambers and it simply pulls air from the air tanks and send it directly to the brake chambers four feet away.

Thus reducing brake lag in the system.

The manual--it says--that the emergency line, the supply line, fills up the air tanks at the trailer or the dolly converter and yes that's what it does.

This is called the supply line.

As well, it also provides air into the spring brake chambers to cage the springs and hold off the parking brakes while you're going up and down the road.

Again the trailer is the same as the truck: if you have an air loss in the trailer, enough air pressure to hold those springs off and eventually those springs will come on and act as emergency brakes in the event of a catastrophic air loss in the trailer.

| Again the air tanks on the trailers have drain valves and have to be drained daily, daily, daily, daily. |

That's the answer to the question on the test.

Drain the air tanks daily.

6.2.7 – Shut-off Valves

If you're pulling multiple trailers or the trailer that you were hooked to the back of the tractor has the capability of hooking another trailer onto the back of it--often via a dolly converter--there will be shut off valves on the back of the trailer for you.

This allows you to hook up airlines to another trailer and supply air to that.

So you have trailer brakes on the second or third trailer.

Shutoff valves simply control the air supply for multiple trailers.

6.2.8 – Trailer Service, Parking and Emergency Brakes

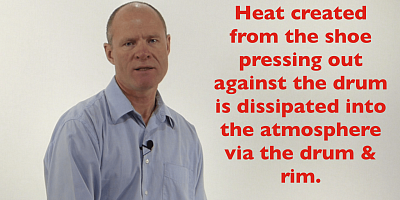

Trailer service parking and emergency brakes - All trailers in this day and age - you're going to have spring brakes on them and theses are used for parking and spring brakes.

The same as on the trucks, and I'll put a link up here for you for the service brakes, the parking brakes, and the emergency brakes on trucks.

They work exactly the same as they do on trailers.

Pre-1970 - dolly converters and trailers will not have spring brakes.

However in the event of a catastrophic air loss, the emergency brakes have to apply, which essentially, as long as there's air in the air tanks, the brakes will apply and will stay applied as long as there's air in the air tank.

However, that's probably not going to happen, but pre-1975 you need to know that for the purposes of a road test.

That even though they don't have spring brakes, they do have emergency brakes and this is where the term "dynamite" comes from, which still lingers around in the trucking industry.

And when air pressure drops in the system and the two buttons on the dash pop out, applying the spring brakes, many drivers still say all the breaks dynamited! NO, the brakes didn't dynamite, the parking brakes applied.

The emergency brakes came on because there wasn't enough air in the system to hold the springs off anymore.

And the emergency brakes applied, but if you hear the term "dynamite" that's what it means.

That these vehicles that don't have spring brakes - there's a catastrophic air loss in the emergency line and it causes the brakes to apply and they will stay applied for as long as there's air in the air tanks.

ABS (Anti-lock braking System) brakes on trailers.

I'll put a link up here to the first video, where I go over extensively ABS on trucks and trailers.

6.3.1 – Trailers Required to Have ABS

Check down in the description box and you'll find the exact chapter mark for the section on ABS in that video.

A quick review - if there is ABS on the trailer, there will be a light on the driver's side near the rear of the trailer that will tell you that there's a ABS on the trailer.

If you're not sure, climb underneath the trailer and have a quick look for the airline out to the brake chamber.

There will be an electrical line running along the airline - it will be zippy tied to it.

That will tell you that there's ABS on the trailer.

Now one of the things that they caution you about is if you have a combination vehicle--truck and trailer--and either the trailer or the truck doesn't have air brakes and the other piece does.

Potentially this combination could cause you to lose control.

So what you have to keep in mind is when your hard braking in an emergency situation, the ABS dictates that you push down on the brake pedal and hold it - pushback, shutter, noise - all of those things are common for ABS brakes.

ABS brakes do not stop you in a shorter distance, rather they're designed for you to keep steering control and the wheels don't lock up as you're going down the road.

If you have a combination vehicle where one piece of the unit has ABS and the other doesn't, you could potentially cause a lock up and jackknife because one is locked up solid and the other is working kinda normally.

So you got to keep that in mind while you're going up and down the road with a combination vehicle where one piece does have ABS and the other doesn't.

That's the caution that they're putting in place in terms of the manual.

As well, the CDL manual, by the time you get done reading and studying it for the purposes of your license, you should know all about ABS brakes, because I noticed that they go over ABS brakes no less than four times in the manual.

Review Questions

Section 6 for the review questions - what I suggest you do is turn the video off, go through the questions, answer them yourself, go through the manual if you have to, but answer the questions and then come back to turn the video back on, and we'll go through the review questions together.

Why should you not use the trailer hand valve while driving?

The reason you shouldn't do it is because potentially you could lock up the trailer wheels and cause the trailer to jackknife.

That is the reason you don't use the trailer hand valve while you're driving.

Use the foot valve and it will apply all the brakes on the vehicle equally.

And therefore you will have nice even braking and you won't risk jackknifing the trailer.

As well, many of these hand valves are not spring loaded and you can't sort of get a sense of how much pressure you're putting to the trailer until you look in the mirror and see it's starting to come around.

So don't use it because you could risk a jackknife.

Describe what the trailer air supply control does?

I'm pretty sure they're talking about the trailer air supply valve on the dash.

It's the eight-sided red button on the dash.

The trailer air supply valve… The trailer air supply shuts air on and off to the trailer, thus the trailer air supply valve - you push it in & you put air to the trailer.

It fills up the reservoir and it also puts air into the spring brake chambers, releasing the spring brakes - the parking brakes on the trailer.

As long as you have sufficient air supply in the trailer, the parking brakes will remain off and not act as emergency brakes.

As well, the trailer air supply - think of it like a light switch.

it doesn't control the trailer parking brakes - it actually controls air supply to the trailer.

Just like a light switch controls electricity.

The subsequent action--like the electric light switch-- turns the light off and on, the trailer air supply also turns the parking brakes on and off on the trailer.

Describe what the service line is for?

The service line is the blue line and can be called either the service line or the control line.

The service line controls the service brakes on the trailer.

When you're going up and down the road, whether you make a hand valve application or you make a foot valve application, it will apply the service brakes on the trailer.

And the way to remember that it is the blue line: it controls the service brakes on the trailer.

What is the emergency line for?

The emergency line is red and can be either called the emergency line or the supply line.

When everything is working normally, the red line to the trailer supplies air to the air tank and air into the spring brake chambers and keeps the spring brakes off.

While you're going up and down the road-- in the event of a catastrophic air loss in the trailer equipped with air brakes-- the tractor protection valve will detect their loss in the trailer and tell the trailer air supply valve on the dash to shutout air to the trailer.

When air is shut off to the trailer, the spring brakes apply, automatically applying the emergency brakes and you are going to come to a screeching halt on the roadway.

Why should you use wheel chocks on a trailer that doesn't have spring brakes?

Because once the air bleeds off in the air tank there's no brakes on the trailer and it could potentially roll away.

And in the ole' days, a lot of trailers got pushed off train cars, pushed over hills and unfortunately a few porta-potties got killed in the process.

So you know post-1975m we determined that we needed to have some way of securing the vehicle indefinitely while parked.

So we put spring brakes on them.

If the trailer doesn't have spring brakes, as you'll be able to detect by looking underneath the undercarriage and seeing the brake chambers.

You'll note that they're a lot smaller, because is only a service brake chamber, therefore you need to block the wheels before you unhook and leave it unattended for any period of time.

What are shut off valves?

Shut off valves allow you to pull multiple trailers and on the back of the trailer, there will be shut off taps on and off that if you hook on with a second trailer.

You can put airlines to it, open the taps, and put air out to that trailer.

So that you'll have brakin capability on that trailer.

Service brakes, parking brakes, and emergency brakes.

In conclusion, trailers equipped with air brakes will have all of the same components as trucks equipped with air brakes.

They have air tanks, lines, brake chambers, pushrods, slack adjusters, a "S" cams, brake pads, linings, and drums are all the same components.

Slight differences: any truck that is capable of pulling trailers fitted with air brakes will have a tractor protection system on it.

The tractor protection system consists of the tractor protection valve and the trailer air supply.

The tractor protection valve detects air loss in the trailer in the event of catastrophic air loss.

In air brake equipped trailers, it will tell the trailer air supply to shut off air to the trailer.

Subsequently, when air is shut off to the trailer, the spring brakes will apply, acting as emergency brakes and you will come to a screeching halt.

There're two lines to hook up to the trailer to supply it with air.

Those two lines are the control line and the emergency line.

One is blue & one is red.

The red always goes on the driver's side.

The couplers to hook up the lines to the trailer are called glad hands.

Question on the test is: what is the most common cause of air loss in a trailer?

It's defective glad hand seals.

As well, hand valve will apply the service brakes on the trailer independently of the truck.

The hand valve is not to be used for parking and not to be used when you're going up and down the road because you could lock up the trailer brakes and potentially risk jackknifing.

Finally, if you're pulling a trailer that doesn't have spring brakes on it and you unhook it, you need to chock the tires so that it doesn't roll away and potentially cause property damage or risk life and limb of other people in and around the area.

So block the wheels of a trailer that you're pulling that doesn't have spring brakes.

And in this day and age, it's really unlikely that you're going to pull any trailer that doesn't have spring brakes.

Salutations

I'm Rick with Smart Drive Test.

Thanks very much for watching.

If you like what you see here share, subscribe, leave a comment down in the comment section.

All of that helps us out.

As well, if you're embarking on a road test for a CDL license, check out the videos below - lots of great information there for you to be successful on your road test.

And as well, if you're working towards a career as a bus or truck driver - check out the videos on the channel.

Lots of great information for you to get started in your new career.

If you're on a mobile device check out the cards in the upper right-hand corner.

Those to will give you links to the videos for the information that you need to be successful on your road test and as a career as a bus or truck driver.

Question for my smart drivers - have you ever pulled a trailer that didn't have spring brakes on it? Was it an older trailer or was it a new trailer like a lowboy or some kind of trailer that didn't have spring brakes because it had low clearance on it and you couldn't get spring brakes underneath it.

Leave a comment down in the comment section - all of that information helps us out and helps out the new drivers who are working towards their CDL license and a career as a truck or bus driver.

Thanks very much for watching.

I'm Rick with Smart Drive Test.

Good luck on your road test.

Remember, pick the best answer, not necessarily the right answer.

Have a great day.

Bye now.