mobi

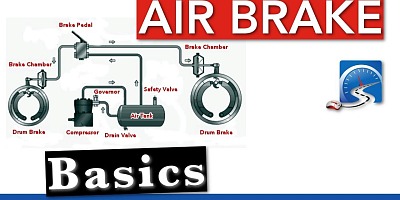

On an air brake system, the air dryer filters moisture and other contaminants from the compressed air. Watch the video!

How the Air Dryer Works | Air Brake Smart

Closed Caption

Introduction

Hi there smart drivers Rick with Smart Drive Test talking to you today about air brakes and specifically the air dryer. I had a comment from Mike9889 and noah arce, both of them wanted a bit more information about the air dryer.

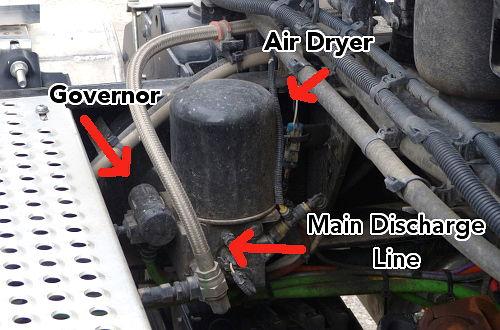

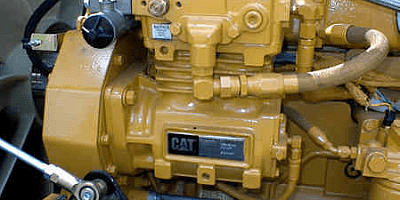

The air dryer on all vehicles is located between the compressor and the first air tank, whether that's the supply tank or if it's an ADIS--an Air Dryer Integrated System-- it will be located between the air compressor and the two tanks - the primary and secondary tank in the system.

In this day and age. all air dryers look the same: they look like a top hat.

They can be located pretty much anywhere on the vehicle.

I've seen them on the front of the truck, underneath the cab, up underneath the frame at the back of the cab. So they're in different places on the unit.

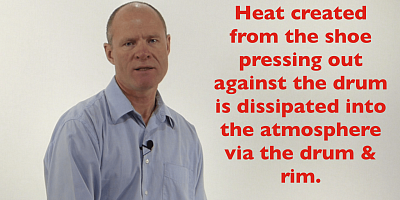

Essentially all the air dryer does is clean the air. These remove moisture and other contaminants that are found in the air after the air is compressed.

And as well, the air dryer prevents freezing in the system because it removes moisture.

| PASS CDL Air Brakes First Time - take this comprehensive course! | |

|

A course for truck, bus & RV drivers operating a vehicle fitted with air brakes.

• more than 100 practice test questions with feedback; |

Illustrations, checklists, & cheat sheets ensure your success

So today we're going to give you a bit more information about that.

First, we're going to go over the older systems that have supply tanks (wet tank) and we're going to go over the new modern air brake systems that have ADIS systems--air dryer integrated systems-- which have made the wet tank redundant.

So stick around, we'll be right back with that information. [OPENING CREDITS & MUSIC]

Preventing Damage to the Air Brake System

Hi there smart drivers, welcome back. Rick with Smart Drive Test talking to you today about air brakes and specifically the air dryer.

The air dryer, simplistically speaking, removes moisture and other contaminants from the compressed air before it enters the main air brake system.

And by removing contaminants, it prevents damage to the system and by removing water it prevents or eliminates the chance of that water freezing in the main air brake system and causing it to fail during cold weather.

Location of Air Dryer

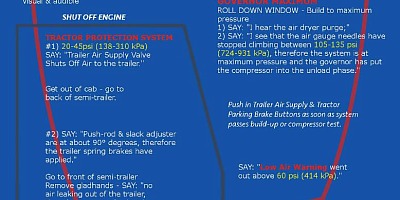

All air dryers are plumbed in to the system between the compressor and the first tank.

On older systems that first tank is going to be the wet tank. And it's called the wet tank because the hot air that comes out of the compressor goes into the wet tank, it cools and the moisture inside of the air comes in contact with the cold metal of the tank, and the water inside condenses.

On older systems you needed a wet tank because the air dryers were not very efficient - you got a fair bit of moisture and that moisture was collected in the wet tank and drained and expelled from the system before it could do damage or potentially cause freezing in the winter time.

Now simply speaking, air dryers are nothing more than a filtration system.

Most modern air brake systems are equipped with an ADIS (Air Dryer Integrated System), which elimates the wet tank (supply tank). An ADIS system can be identified by the governor being within close proximity to the air dryer. As well, when building air pressure, one sub-system will fill to approximately 100psi and then the other sub-system will fill.

Nothing More than a Filter

The air dryer itself is filled with a desiccant and essentially a desiccant is nothing more than kitty litter.

And the compressed air under high pressure is forced through the kitty litter and the kitty litter collects the moisture and other contaminants that are found in the compressed air.

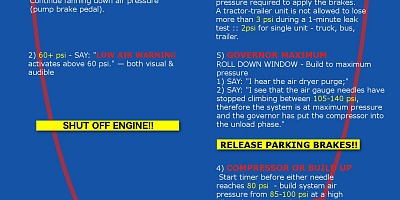

When the system maintains maximum pressure--on most systems that's going to be between a hundred pounds and a hundred thirty-five pounds--most systems in this day and age you're gonna run run around 125 pounds per square inch mark.

When the air brake system maintains maximum pressure, the air dryer purges or expels and it kicks out all the contaminants.

So if the the air brake equipped vehicle has been sitting there running for a while you'll begin to see a spot on the ground - a bit of moisture and whatnot.

If you see an excessive amount of moisture that means there's something wrong with the air dryer or compressor. For the most part, you'll just see a bit of moisture on the ground.

Purges at Maximum Pressure

As well, when the vehicle is idling and you're walking by and goes PSSSSST [FEIGNING FRIGHT & LAUGHING] and it scares the crap out of you - that's the air dryer - and you know the system is at maximum pressure because the air dryer purges at maximum pressure.

So you'll know what it is. And when you're doing your in cab pre-trip inspection and you're waiting for the system attain maximum pressure, the first thing you're going to hear is the air dryer.

And as many drivers' manual state: the air dryer is not the only indicator that the air brake system is at maximum pressure.

Yes it is the first indicator, but you must also look at the air gauges and confirm that in fact the system is between a 100 psi and a 135 psi to confirm that, in fact, the system is at maximum pressure.

But because we react to sound first, we're going to hear the air dryer purge.

Some of the newer systems, the air dryer is actually quiet, so you're going to have to roll down your window and listen for that air dryer purging to know the system is a maximum pressure.

So older air brake systems are going to have a wet tank.

The air dryer is going to be between the compressor and the wet tank. It will purge at maximum pressure and it is a filtration system that is filled with desiccant, and as i said in the introduction, these air dryers can be located in number of places on the vehicles: on Freightliners, they're up in the passenger corner, right up underneath the engine compartment; on Western Stars.

I've seen them up underneath the cab; and on an International, I've seen them at the back of the cab up underneath the frame.

So I've seen them in different locations throughout the vehicle on different makes and models. So you just have to look around.

Shaped Like a "Top Hat"

All air dryers have the same shape, as seen here in the image. The air dryer can be found almost anywhere on a vehicle - in the engine compartment, under the cab, or behind the cab bolted to the frame.

Most of them in this day and age are all going to be shaped like a top hat. You can see a picture of one here in the image, and you see that shape and you know it's going to be the air dryer.

I have seen on some really, really old trucks--1980s and 1990s--they are a bit different shape, but for the most part they're going to be the same shape.

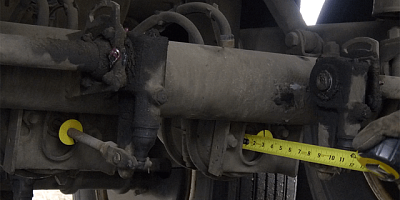

It's easy to locate when you do your conducting your pre-trip inspection - you just basically look at them and say: "there's no excessive amount of moisture or water underneath the air dryer, and as well, it's not cracked or damaged and they don't have any leaks.

So essentially that's all you have to do for a pre-trip inspection.

And it will be the indicator that the system is at maximum pressure as I already went over. On an older system you have a wet tank and for the purposes of a pre-trip inspection, after you secure the vehicle by chocking the wheels and releasing the parking brakes, you're going to drain the wet tank.

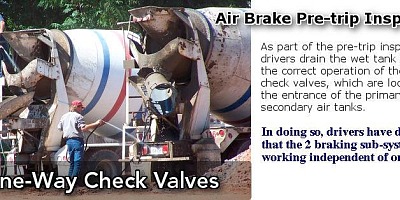

And the reason you drain the wet tank first is to check to make sure that the 2 one-way check valves at the entrance to the primary and secondary tank are operating normally.

Secondary & Primary Sub-Systems (Fail-Safe)

Because those two one-way check valves are primarily responsible for the division of the air brake system into a primary and secondary subsystem.

So on older systems that have a wet tank, that's the first thing you're going to have to do. And to locate the wet tank on an older system, you go into the truck and take note of what the air pressure is on the gauges.

Then you go out and start draining tanks. The tank that doesn't drain the gauges on the dash is your wet tank, because the wet tank doesn't have a gauge on it.

Most modern air brake systems all have ADIS systems - air dryer integrated systems, which essentially means that they have eliminated the wet tank. So they don't have a wet tank.