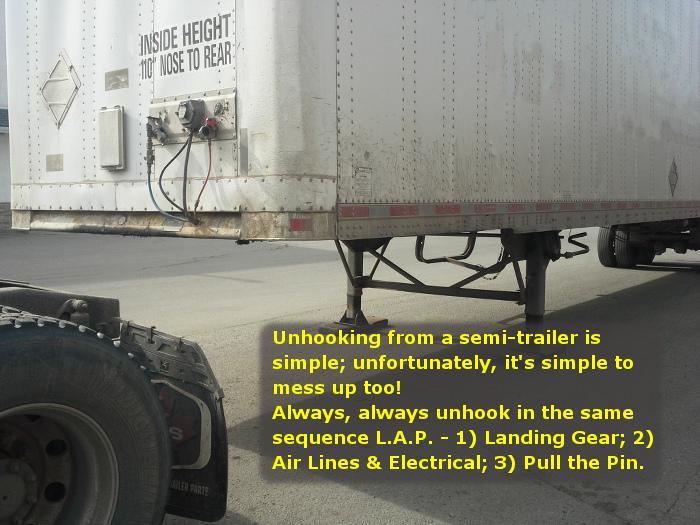

Before unhooking a semi-trailer, ensure that the ground will support the weight of the landing gear.

Before unhooking a semi-trailer, ensure that the ground will support the weight of the landing gear.

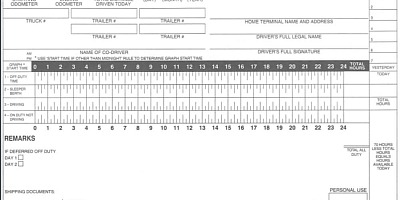

MUST KNOW

LAP

1) Landing Gear down

2) Air Lines & Electrical (Disconnect)

3) Pin (Pulled & Unlocked)

SHOULD KNOW

Park the trailer in a safe & preferably secure location.

A safe location is ideally a place away from the flow or path of traffic.

Attempt to park the trailer away from a roadway, or in a yard near the main travel path of other vehicles – ie. employees’ vehicles, forklifts and other trucks.

Ensure that the ground will support the weight of the trailer – if not, use planking under the dollies or find another location.

If the trailer is equipped with an air suspension dump valve – empty the semi-trailer's air suspension.

Wind down the landing gear until it just touches the ground - drop or stow the crank handle.

Trailers are parked close together (12-18" (30-45cm); if the crank handle is left in the cranking position another driver may back into it and potentially damage it.

The next driver (usually you) to arrive will find a broken crank handle, and ultimately be delayed.

Disconnect the air lines and electrical chord and stow in the dummy couplers or secure to the deck plate with a bungee chord.

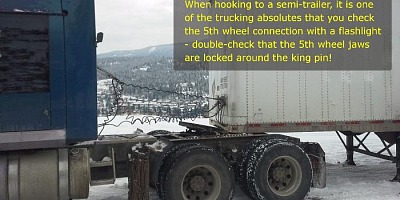

Pull the 5th wheel handle to release the jaws – preferably using a 5th wheel puller.

Pull the 5th wheel handle to release the jaws – preferably using a 5th wheel puller.

If you don't use a 5th wheel puller you're probably going to get grease on your sleeve, and that grease on your sleeve then ends up in your truck - just another sign of professionalism.

Climb in the cab and move the tractor ahead 6-12" inches using “bull” or low gear.

Stop the truck and dump the tractor’s air ride suspension.

Get out and check for daylight between the 5th wheel plate and the trailer apron - this indicator tells you that the ground is supporting the weight of the trailer.

Get back in the cab – pull out completely from under the trailer – you’re done!

COULD KNOW

Dropping the trailer on solid ground

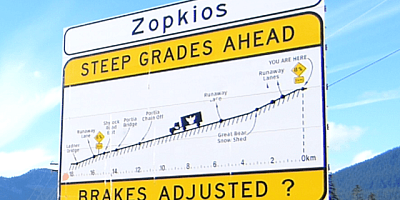

If you don’t inspect the ground before dropping the trailer, it could potentially sink.

If this happens, you—yes you the driver—will be held responsible for negligently dropping a trailer.

Never drop a trailer on pavement without putting wood under the feet.

In some trailer yards, a strip of concrete is poured and the trailer’s dollies must be positioned on the concrete to prevent damage to the pavement.

Dumping the air ride suspension on a loaded trailer before disconnecting prevents potential damage to the landing gear.

Over time as a loaded trailer sits, the air ride suspension bleeds off.

As the air ride suspension gradually deflates, the rear of the trailer sinks; consequently, forward pressure is exerted on the landing gear which potentially bends the legs and struts.

When unhooking the trailer, always, always wind the landing gear down first, otherwise you may get distracted and forget.

By establishing a procedure of doing the landing gear first, you will never risk potentially unhooking a trailer and dropping it on the ground.

Immediately after winding down the landing gear, disconnect the airlines and the electrical chord.

If you wind down the landing gear and then pull the 5th wheel pin, again, you may get distracted and forget to disconnect the lines.

And believe me you: there is nothing that will make you look more amateur than driving away from a trailer and snapping off the air lines and electrical chord.

This error is tantamount to driving away from the fuel pump with the fill spout in your tank.

If you wind down the landing gear and disconnect the lines, but forget to pull the pin, no one will know other than you.

After a bit of embarrassment, you simply get out of the truck and pull the pin.

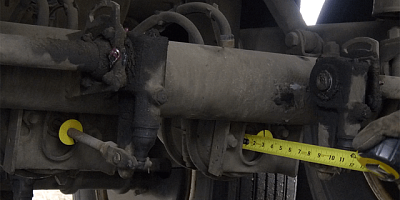

Before dumping the tractor’s air ride suspension, move the truck forward slightly to disengage the king pin from the 5th wheel jaws.

The trailer’s king pin has a flange on the bottom, and if you lower the truck while the king pin is still inside the 5th wheel , the 5th wheel jaws could potentially “hang up” on the king pin’s flange.

If the king pin hangs up inside the 5th wheel, it could damage both the king pin and the 5th wheel coupling mechanics.

If this undue stress occurs regularly, the 5th wheel may fail altogether.

Finally, don’t just pull out from under the trailer and drive away.

If you pull out only far enough that the trailer comes off the back of the 5th wheel and stops, you can still get the tractor back under the trailer if the ground fails to support its weight.

Otherwise, if you pull the tractor out and the trailer sinks, a crane or heavy fork truck will be required to get the trailer back up to a level that it can be hooked to a truck.