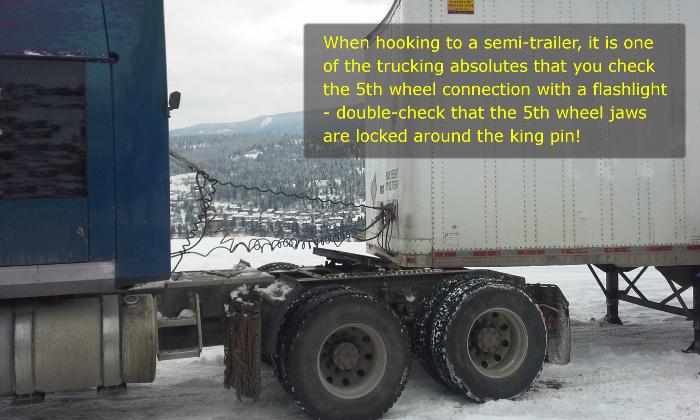

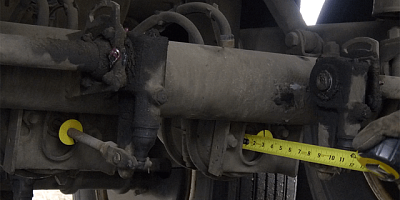

Always check with a flashlight that the 5th Wheel jaws are locked around the king pin.

MUST KNOW

P.D.A.

WAYS TO REMEMBER PDA - Public Displays of Affection OR Personal Digital Assistant (for the older drivers that remember Palm Pilots (ca 1990s)

1) Pin

2) Dollies (Also called Landing Gear)

3) Air Lines & Electrical

SHOULD KNOW

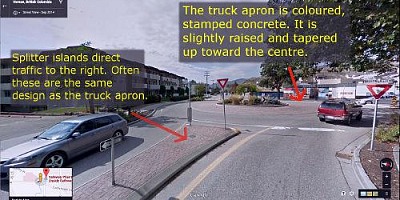

- Line up truck with trailer – sidewalls of truck duals should be 1-2” in from the edge of the trailer

- Back up until the front of the trailer is at the centre point of the front rear tires - STOP & apply brakes

- Apply the parking brakes and get out of the truck

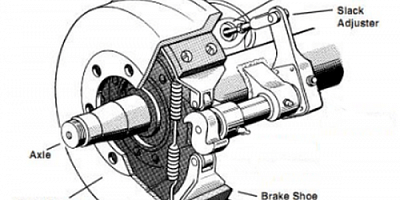

PIN

Stop at the mid-point of the truck's duals and check:

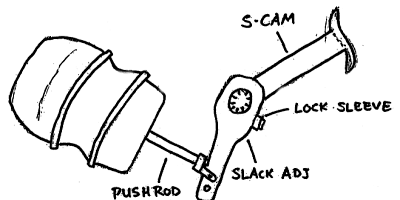

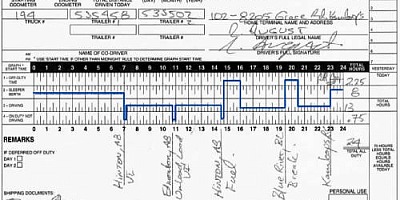

- The handle is out

- The adjusting nut is out

- The 5th wheel is secure to the frame

Go under the trailer directly behind the truck:

- The fifth wheel jaws are in line with the King pin

- The 5th wheel jaws are open

Reach in the truck, and raise the air suspension

- Check that there isn't any daylight between the trailer apron and the 5th wheel plate - this indicates that the trailer is at the correct height to hook-up

Go back in the cab

- Back under the trailer until you can hear the jaws close – or you bang against the pin

- Get out of the truck:

- There is no light between the fifth wheel and the trailer apron

- The adjusting nut is in the locked position

- The locking handle is in the locked position

- The locking dog is engaged OR the 5th wheel is secure to the frame

- Go under the trailer – the jaws are locked behind the king pin

Crank up the dollies 1”

Re-enter the truck and perform a tug test in low gear

DOLLIES (LANDING GEAR)

- Get out of the truck – crank up the dollies and stow the crank handle

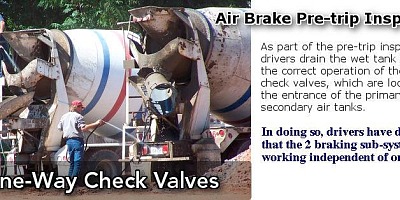

AIR LINES & ELECTRICAL

- Hook up the air and electrical lines

SAY: "If this was a new trailer, I would perform a complete pre-trip inspection on the unit."

COULD KNOW

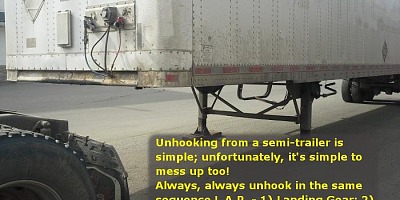

If you back into the trailer and hook up the air lines and electrical before cranking up the dollies (landing gear), and you become distracted.

You could potentially damage the landing gear if you forget to wind these up before pulling away.

If you don't check the height of the trailer before backing under, you could potentially drop the king pin over the front of the 5th wheel.

Often you need a chunk of 2X4 and a lot of muscles; the 2X4 is to jam in the front of the 5th wheel and hold it down and forward.

The muscles are to crank the trailer higher with the dollies.

If the trailer is empty, cranking it up isn't too bad, but if it's loaded, you'll need the strength of 4 elephants and the magic of Houdini to get that trailer even a couple of inches higher.

Save yourself the grief and just get in the habit of checking the height of the trailer before backing under - EVERY time!!

Ensure that you check that the 5th wheel jaws are closed around the king pin.

The only way to do this correctly is with a flashlight - it takes 20 seconds and will give you piece of mind.

Like blowing up a $25,000 diesel engine because you didn't check the oil or oil pressure gauge, the infamous "they" get really excited when you drop a semi-trailer off the back of a truck because you didn't check that the 5th wheel connection was secure before driving away.